Ergonomic die Casting Machine For Copper And Copper Based Alloy

| Brand Name: | DZ |

| MOQ: | 1 |

| Packaging Details: | Packing in wooden cases suitable for sea transportation |

| Payment Terms: | L/C, T/T, Western Union |

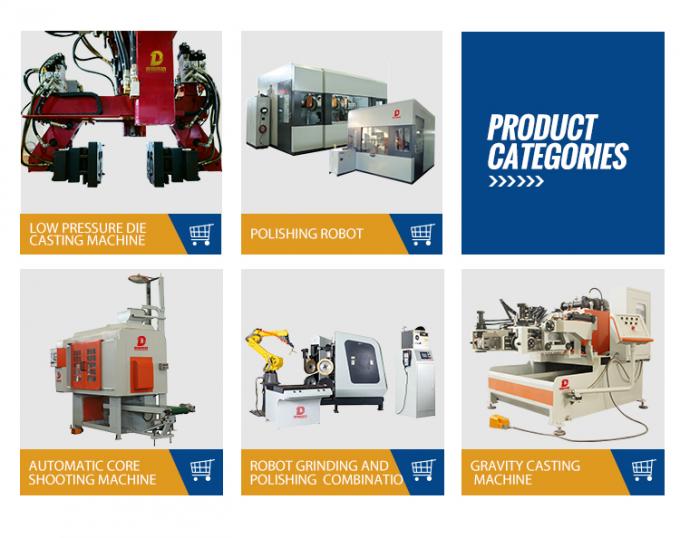

Ergonomic Die Casting Machine

,Copper Based Alloy Die Casting Machine

,Ergonomic Die Casting Equipment

Casting Machine Furnaces/Plants For Copper And Copper-based Alloys

| Number of robots | 1 |

| Electric furnace power | 3*35KW |

| Electric furnace melting rate | 350KG |

| Air pressure | 6KG |

| Water source pressure | 3KG |

| Maximum furnace temperature | 1250 |

| Cooling water temperature | 18-22 |

| Robot's fastest moving speed | 20m/min |

| Maximum lifting weight | 500KG |

ADVANTAGES

1. Cost-efficient production

- Multiple cavity dies

- Reduced melting loss

- Increased yield (less circulating material)

- One-man operation

- Cost savings in subsequent stages of manufacture

- For robotic grinding low pressure die casting is a must

2. Humanization of the workstation

- Ergonomic design of the workstation

- Minimizing of smoke, heat, noise and danger of accidents

3. High quality castings and high-precision repeatability

- Automated casting

- Oxide inclusions in the casting are prevented by feeding metal from inside the melt through the riser tube

![]()

![]()

![]()

![]()

![]()

![]()

Q: Could you please arrange the installation and commissioning ?

A: Yes , we could and the buyer pay the charge.

Q: Could you arrange the production education?

A: Yes , we could and the buyer pay the charge.

Q: How long the guarantee?

A: One year and charge for repair the whole life.

Q: How about the lead time and delivery time of my order?

A: Large cargo 15-25 working days, depending on the quantity, and delivered according to the agreed time.