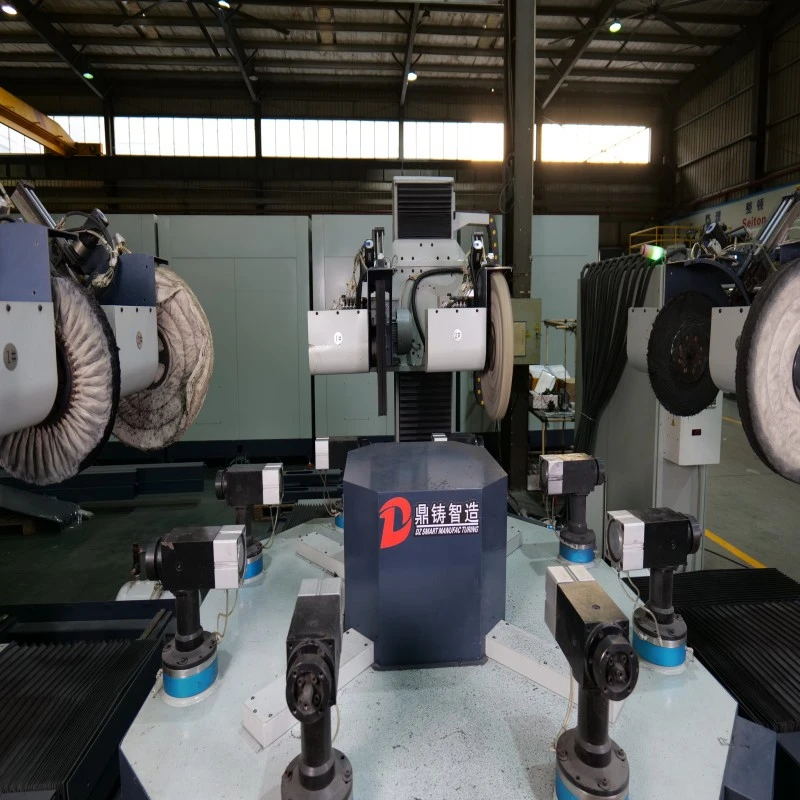

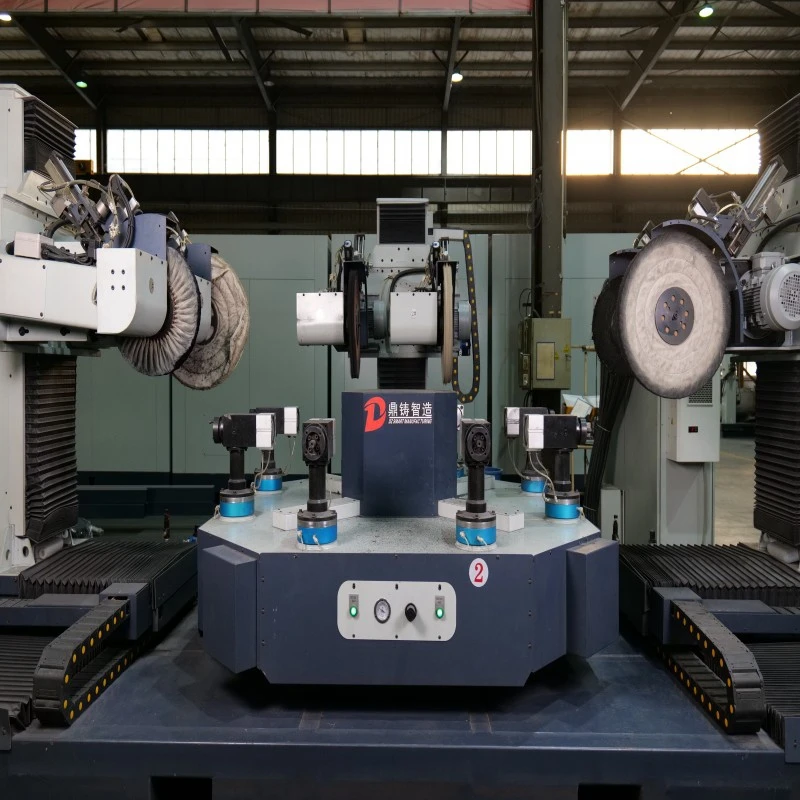

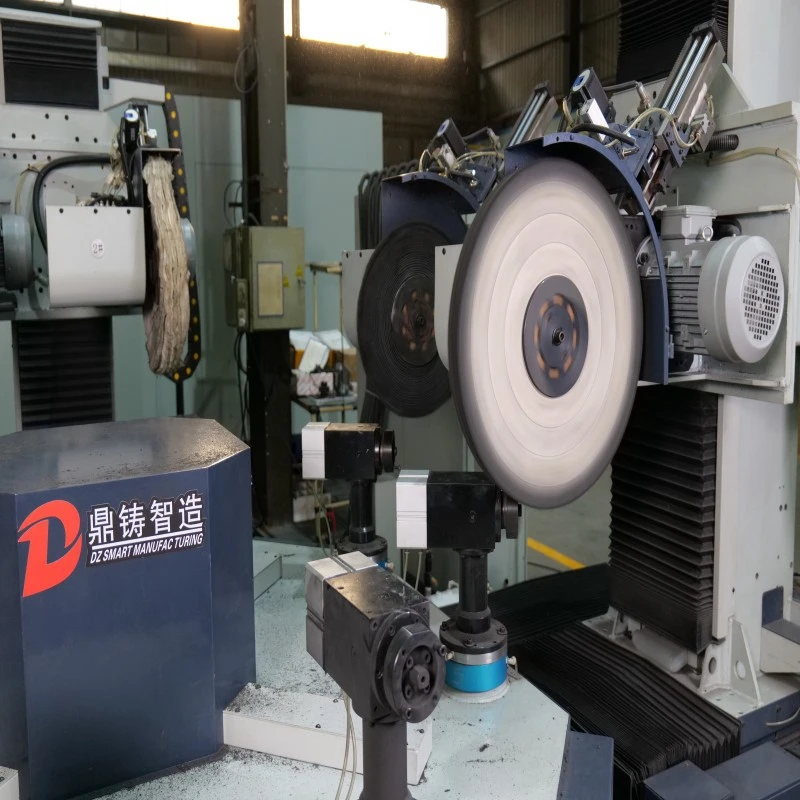

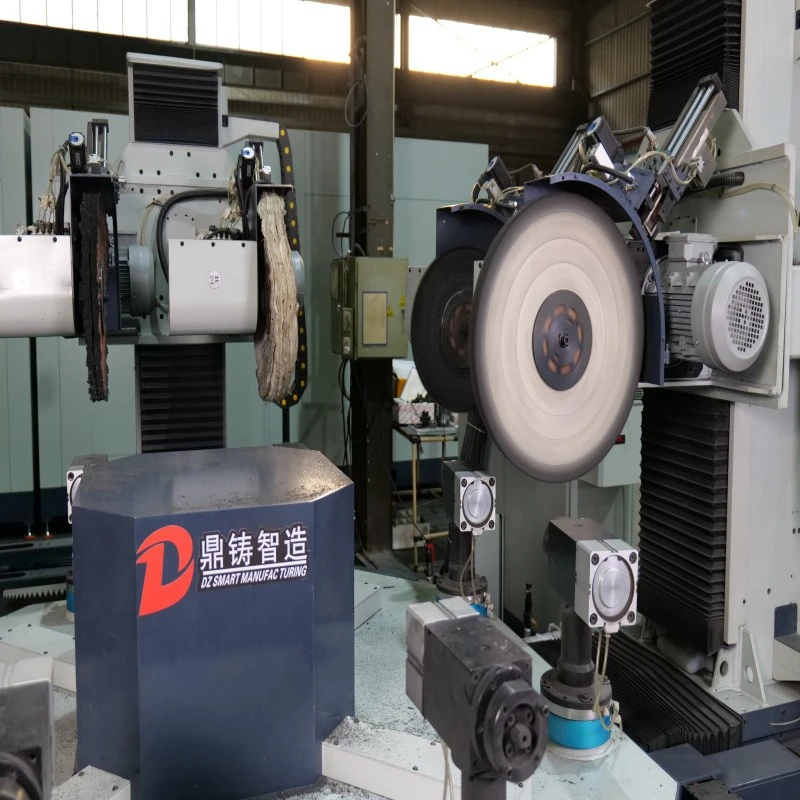

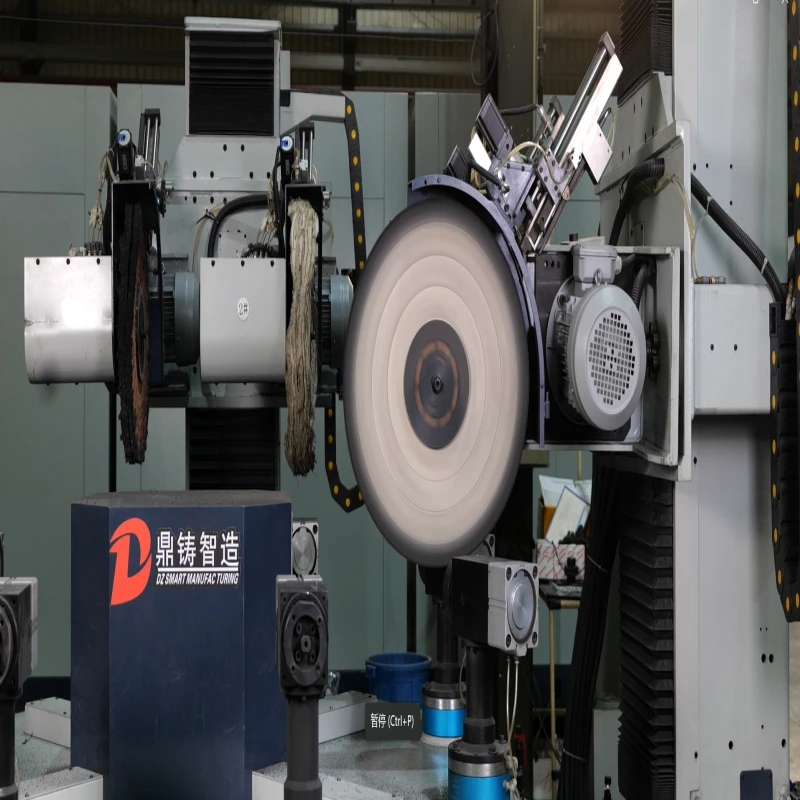

CNC Polishing Machine For Automatic Coordinate Compensation Aluminum Car Wheel Hub Faucet Hardware Castings

| Brand Name: | DZ |

| Model Number: | HLD-50E |

| MOQ: | 1 set |

| Packaging Details: | wood |

| Payment Terms: | L/C,T/T,Western Union |

Detail Information

Place of Origin:

China

Certification:

CE

Weight:

4000KG

Voltage:

380V/50Hz

Condition:

New

After-sales Service Provided:

Engineers Available To Service Machinery Overseas,Video Technical Support,Online Support,Field Maintenance And Repair Service,Field Installation

Use:

Machining, Deburring, Grinding, Polishing

Type:

Angle Polisher

Warranty:

1 Year

Function:

Machining, Deburring, Grinding, Polishing

Delivery Time:

30 days

Supply Ability:

30sets / month

Highlight:

Faucet Hardware Castings CNC Polishing Machine

,Automatic Coordinate Compensation CNC Polishing Machine

Product Description

Product Description

Product Feature:

1.Efficiency, The automatic polishing machine is an exclusive polishing system consisting 8 heads with of 6 Axis and rotary table ; Multiple stations simultaneous operation ensures high flexibility and high product efficiency. 2.Flexibility, The machine has four stations, each station with two heads. One station is for loading and unloading, the other three stations for polishing. The machine can be produce different products at the same time. 3.Fully Automation, Multiple process can we achvie one different station, rough polishing ,fine polishing depend on different buffing wheels. 4.For more complex products,wheels of different specifications can be installed on the rotaty polishing robot to achieve the comprehensive processing of products, to realize a multi-purpose machine. 5.The control system adopts DZ motion control technology, with stable performance and high control accuracy. 6.Programming method: teaching programming ,with portable handed device, contains manually mode to simulate the workmanship polishing and record the track; automatically operating model is available with pre-set parameters program. 7.Polishing pressure and wear compensation control performance: When the polishing cloth wheel is worn out, the system can detect that the torque has become smaller and automatically the compensation in all directions. 8.Linear speed compensation: When the outer diameter of the cloth wheel is reduced, the system automatically increases the speed and compensation; 9.Program setting of add polishing wax:free setting of wax spraying time and frequency according to the characteristics of product.choice of slid compound or liquid compound. 10.Fully digital control. Programs can be saved and recalled at any time. 11.CN/EN language display on Touch Panel. It is to set all parameters for an easy operation; fault codes display and alarm pages for quick troubles shooting and repair. 12.Lack of wax alarm.

Specification

Company Profile

Xiamen Dingzhu Intelligent Equipment Co., Ltd. (est. 2016) is a global leader in intelligent manufacturing solutions specializing in low-pressure die casting, grinding, polishing, and automation systems. Our core offerings include automatic LPDC machines, robotic cell grinding/polishing systems, CNC polishing equipment, and turnkey production lines, serving industries such as water meter casting, door locks, auto parts, and precision deburring.

With exports to 30+ countries (Turkey, India, Mexico, USA, Southeast Asia, etc.) and partnerships with top brands like Kohler and TOTO, we empower manufacturers with safer, greener, and smarter production through proprietary technologies like dynamic pressure control and multi-axis robotic algorithms.

50+ patents and a 60+ R&D team drive innovations in low-pressure casting and robotic automation. We deliver end-to-end solutions—from mold design (CAE simulation) to lean factory layouts—backed by 24/7 global support, localized service centers (India, Turkey, Egypt), and 48-hour on-site assistance.

CE-certified with strict material inspection and a 1-year warranty, we prioritize eco-friendly practices and operational excellence. Committed to "liberating workers' hands," Dingzhu envisions leading the future of intelligent automation, helping clients achieve productivity breakthroughs and sustainable growth.

Partner with us to transform your manufacturing with cutting-edge technology and world-class expertise.

Our Case

Exhibition

Certifications

Packing & Delivery

FAQ

1. Who are we?

We are based in Fujian, China, start from 2016,sell to Domestic Market(30.00%),South America(10.00%),South Asia(10.00%),Mid

East(10.00%),Oceania(10.00%),Africa(10.00%),Southeast Asia(10.00%),Eastern Europe(10.00%). There are total about 11-50 people in

our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Automatic cleaning machine,Robot polishing machine,Two-station low pressure casting machine,Sand shooting machine,Casting machine

4. Why should you buy from us not from other suppliers?

Xiamen Ding Zhu intelligent equipment Co., Ltd. is committed to the research and development of bathroom, hardware industry

intelligent production equipment, the main products are: non-ferrous metal low-pressure casting equipment, six-axis polishing

machin

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese,Japanese

We are based in Fujian, China, start from 2016,sell to Domestic Market(30.00%),South America(10.00%),South Asia(10.00%),Mid

East(10.00%),Oceania(10.00%),Africa(10.00%),Southeast Asia(10.00%),Eastern Europe(10.00%). There are total about 11-50 people in

our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Automatic cleaning machine,Robot polishing machine,Two-station low pressure casting machine,Sand shooting machine,Casting machine

4. Why should you buy from us not from other suppliers?

Xiamen Ding Zhu intelligent equipment Co., Ltd. is committed to the research and development of bathroom, hardware industry

intelligent production equipment, the main products are: non-ferrous metal low-pressure casting equipment, six-axis polishing

machin

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese,Japanese