Hot Chamber Gravity Die Cast Machine For Foundry Pieces Production

| Brand Name: | DZ |

| Model Number: | HZ-450 |

| MOQ: | 1set |

| Price: | Negotiable |

| Packaging Details: | wood |

| Payment Terms: | L/C, T/T, Western Union |

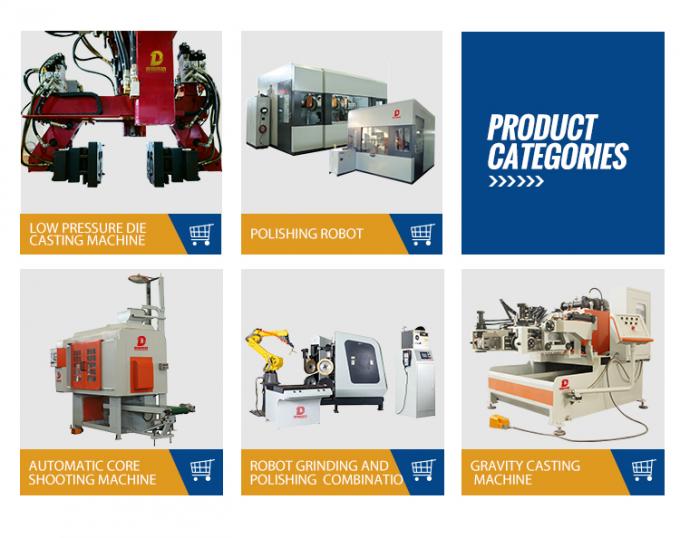

Foundry Pieces Die Cast Machine

,Plc Controlled Gravity Die Cast Machine

,Foundry Parts Gravity Die Cast Machine

Faucets Manufacturing Manual Weight Continuous Casting Machine for Brass

| Maximum combined distance | 250mm |

| Hydraulic pressure | 40-60KPA |

| Hydraulic oil | 163L |

| stroke | 20mm travel |

| Pouring angle | 0°-110° |

| Side pouring angle | 0°-90° |

CHARACTERISTIC

1. The circuit is controlled by PLC, the data is set by touch screen and all hydraulic components are imported.

2. It is suitable for gravity die casting of brass and ferrous alloy.

3. It can be frontal casting, side casting, twice casting and mixed casting.

4. It is possible to individually adjust the cooling time of the die.

5. It facilitates the decomposition, combination and cleaning of dies.

6. It has two functions of manual and automatic circulation, the counter can be preset, to record the output of each shift.

7. There is a die adjustment space to facilitate the application of different dies, and reduce the requirements for the die size.

8. The machine can store the die casting operation programs and set the password accordingly.

![]()

![]()

![]()

![]()

![]()

![]()

Q: Could you please arrange the installation and commissioning ?

A: Yes , we could and the buyer pay the charge.

Q: Could you arrange the production education?

A: Yes , we could and the buyer pay the charge.

Q: How long the guarantee?

A: One year and charge for repair the whole life.

Q: How about the lead time and delivery time of my order?

A: Large cargo 15-25 working days, depending on the quantity, and delivered according to the agreed time.